The Wheelwright

Big Wheels

The wheelwright makes the wheels for a wagon or carriage. These wheels have to be strong enough to support the carriage and anything in it, even over bumpy, rocky dirt roads. Here are some examples of carriages that the wheels might be made for. Notice how big the wheels are! Much bigger than a car or even truck tire.

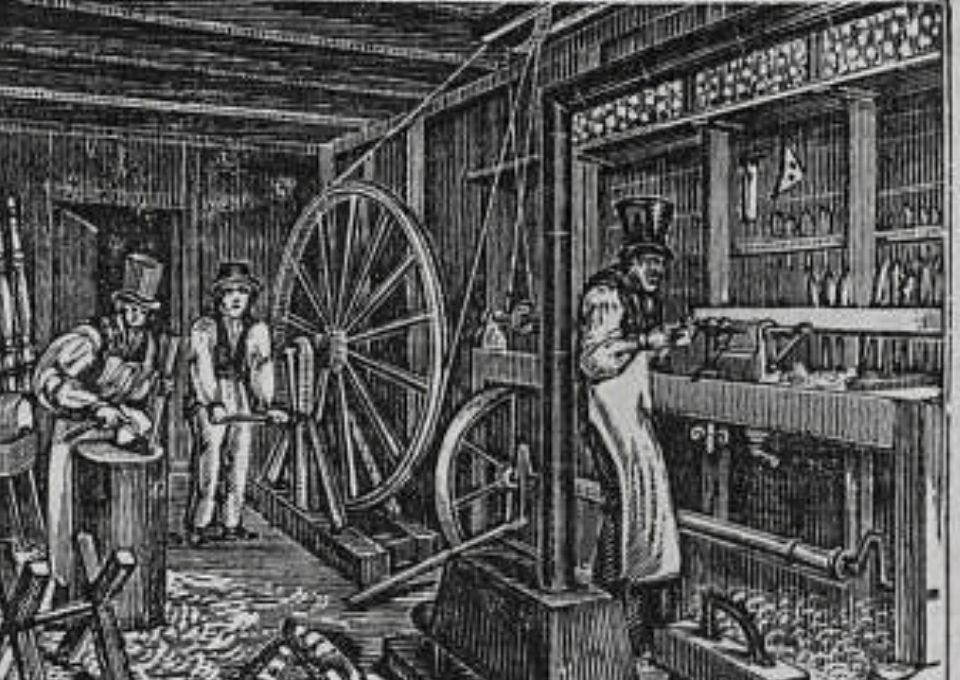

Tools of the Trade

Making a wheel starts in the center with the hub. Think of the hub caps on a car – these cover the comparable part on a car tire. The single hole that runs through the hub is for the carriage axle, a long wooden pole that runs under the carriage. This connection to the axle is how the wheels are able to turn and move the carriage forward.

Next comes the spokes that connect the hub to the felloes or outer wooden rim of the wheel. Compare these to the metal spokes on a bicycle tire. The spokes have to be shaped perfectly in order to fit and be strong enough to hold the weight of the carriage. The spoke shave is used to scrape the spoke into shape the same way you would scrape a carrot and the spoke pointer sharpens the end like a pencil sharpener.

Finally, the wheelwright adds the iron tire around the outside to protect the wooden wheel. In order to make sure this iron strip is exactly the same size as the wooden rim, the wheelwright uses a traveler . This would have had a mark at one point on the circle. The wheelwright would then roll the traveler along the wooden rim, counting how many times the mark was passed. The wheelwright would then roll the traveler the same number of times along the iron strip.

The wheelwright might also use a wheel jack the same way a car jack is used: To prop up the vehicle while the wheel is changed or repaired.